Coating Services

We provide specialized coating solutions to protect, stabilize, and extend the life of your critical pipeline assets.

.png)

.png)

.png)

.png)

.png)

.png)

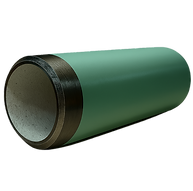

Fusion Bond Epoxy (FBE)

2" - 42" up to 100'

FBE is a thermoset epoxy that is used to protect the OD of the pipe from deterioration over time. Properly coated FBE can extend the life of a pipe by 20 years.

Abrasion Resistant Overlay (ARO)

42" up to 80'

ARO is a thermoset epoxy that is used to protect the FBE from being damaged. It is applied immediately after the FBE and therefore the two can be referred to as a dual coat system.

Concrete Weight Coating (CWC)

We apply a compression style concrete weight coating to pipe and special pieces ranging from 6” diameter and up

Zap Wrap

Zap Lok pipe is pipe that can be installed without any welding. This is achieved by a bell pin system in which the pin end is compressed into the bell end which in turn seals the two joints together. Zap lok is only used on joints up to 12 ¾”. The Zap Lok is coated with FBE and then a 16” powercrete / ARO coating is applied on each end. The Powercrete is used to protect the FBE from damage when the compression unit holds the two joints and presses them together.

Powercrete

Powercrete is the strongest exterior coating that can be applied over the top of FBE in order to protect it. It’s approximately 25-30% stronger than ARO. Powercete is a plural component formula that must be correctly mixed and immediately applied in order to keep from hardening in the lines. It is applied at the rate of 20 mils per coating and can have several applications if more mils are required by customer spec. For application, 4-5 joints are place on rollers that are constantly spinning each joint. The workers sand the FBE as the pipe spins in order to establish an anchor profile for the Powercrete to adhere to. Following the sanding, each pipe is cleaned with an MEK solvent to remove any impurities and dust. The pipe is then coated by hand spraying and allowed to spin until dry. A 4” cutback is used so that 1” of the FBE is visible.

Internal Coating

The internal coatings are to coat the Internal Diameter (ID) of pipe to protect it from degradation or the contents from contamination. First, the pipe must be sand blasted to clean the ID. The ID coating are applied via a specialized internal lance designed specifically for the internal coating system.

Cement Lining

Applied to AWWA C-205 standards

Traceability

Upon arrival, each pipe joint is inspected and assigned a unique barcode using our proprietary system—delivering industry-leading traceability. This barcode tracks ownership, order details, coating type, and key specifications such as diameter, wall thickness, material grade, end type, heat number, length, and weld type.

Womble Company offers accessible transportation—by barge, rail, or truck for you to ship your product directly to our pipeyards to best serve our customers’ logistical needs.